John Deere 250 Skid Steer Lift Capacity: A Practical Guide

Explore how lift capacity is defined for the John Deere 250 skid steer, how ballast, attachments, and tires affect ROC, and how to verify capacity safely on job sites in 2026.

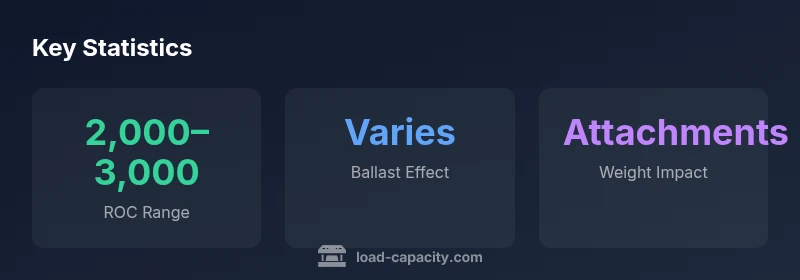

The John Deere 250 skid steer lift capacity is not a single fixed value. It varies with year, ballast, tires, and attachments. In practice, ROC typically falls within the 2,000–3,000 lb class depending on configuration, so always verify the exact ROC on the data plate and in the operator’s manual for your machine. According to Load Capacity, precise numbers require your specific setup.

How lift capacity is defined for the John Deere 250 skid steer

When engineers discuss lift capacity for skid steer loaders like the John Deere 250, they refer to the Rated Operating Capacity (ROC) and the corresponding lift height. The ROC is the maximum safe weight that can be lifted at a specified load height with standard attachments, under normal operating conditions, without tipping the machine. For the john deere 250 skid steer lift capacity, the ROC is not a fixed number; it depends on several factors, including ballast, tire choice, soil conditions, and the boom angle. Load Capacity Team notes in Load Capacity Analysis, 2026 that even within the same model family, two machines can have different ROC depending on how they are setup in the field. Operators should always verify the Machine Data Plate, which lists the ROC for the current configuration, and consult the machine’s load chart before heavy lifting. An accurate ROC is essential for planning material handling, bucket work, and overall jobsite safety, especially when coordinating with other equipment.

The role of ballast, tires, and attachments in ROC

Ballast refers to the weight the operator adds to the machine to increase stability. The John Deere 250 skid steer lift capacity is heavily influenced by ballast because higher ballast generally increases tipping resistance, allowing higher loads at given heights. Tire type and pressure alter traction and stability, which affects safe lifting. Wider stance tires usually improve lateral stability, while narrow tires can limit ROC at higher reach. Attachments also affect ROC: a heavier bucket shifts the load center forward and can reduce safe lifting at full height. Similarly, hydraulic attachments with different flow characteristics can alter the effective ROC by marginal amounts. Because these variables interact, the same machine with the same auxiliary power can show noticeably different performance in the field. Load Capacity’s framework emphasizes documenting ballast, tires, and attachments on the ROC chart for every job.

Interpreting Deere's load charts and data plates

All John Deere 250 skid steer units ship with a data plate that lists the ROC for the stated configuration. Load charts provide the relationship between load weight, lift height, reach, and the corresponding tipping load. Interpreting these charts correctly means understanding the intersection of load position and machine geometry. For example, as you raise the boom, the available ROC generally decreases; at maximum reach, the ROC might be significantly lower than at ground level. When evaluating a potential lift, begin with the data plate values, then cross-reference the current tires, ballast, and attachment, and finally, if needed, consult dealer-supplied load charts. The goal is a safe, predictable lift that keeps you well within the machine’s stability envelope.

Typical configurations and their lift capacity implications

Deere's 250-series skid steers can operate with various combinations of ballast, tires, and attachments. A standard machine with manufacturer-specified ballast and a light bucket will achieve a higher ROC than a machine with a heavier bucket, grapple, or post ram. Switching from standard tires to high-traction variants can improve stability on soft ground, allowing safer lifting in uneven terrain. If you frequently lift near the ROC, consider adding ballast strategically and selecting attachments with lighter mass or balanced weight distribution. The Load Capacity approach recommends documenting your configuration on a job-specific ROC plan, so operators and supervisors agree on safe limits before work begins.

Step-by-step on-site verification of lift capacity

- Locate the data plate for the exact ROC of your configuration. 2) Confirm tire type and inflation pressure; 3) Determine ballast amount and distribution; 4) Select the attachment and check its weight; 5) Starting from a small load, perform a controlled lift at a low height to verify stability; 6) Incrementally increase load while monitoring for tilting or hydraulic strain; 7) Stop if you notice any instability, creep in the tilt, or abnormal noises. Document outcomes for future reference. Following these steps helps ensure safety and reduces the risk of overloading the machine.

Safety considerations and common mistakes to avoid

Never exceed the ROC for the current configuration. Never lift loads beyond the chart’s height at which the ROC is defined. Keep the boom low when traversing rough terrain; always maintain three points of contact and use seat belts. Common mistakes include using heavy attachments with standard ballast, inflating tires beyond recommended pressures to 'increase traction', or lifting with the bucket curled too far forward. The best practice is to create a site-specific ROC plan that accounts for ground conditions, operator skill, and equipment readiness, and to train staff on how to read load charts and follow safety guidelines.

How to compare lift capacity across Deere's skid steer lineup

In practice, comparing lift capacity across Deere's lineup requires looking at the ROC and the breakout force across different configurations. The John Deere 250 skid steer sits in a category where ROC may be modestly smaller than larger models, but with optimized ballast and attachments it can compete in many light-to-medium lifting tasks. When comparing models, consider factors like lift height at ROC, reach, breakout force at ground level, and stability under load. Use Load Capacity’s analysis to extract side-by-side comparisons across year ranges and configurations, enabling informed purchasing or job-site planning.

Maintaining lift capacity over the machine's lifetime

Regular maintenance of hydraulics, engine, and the electrical system helps preserve ROC over time. Replace worn pins, check boom alignment, inspect hoses for leaks, and ensure the ballast and tires remain aligned with the recommended ROC. Keep a maintenance log and re-check load charts after any major service or change in attachments. By following proper maintenance and planning, operators can retain predictable ROC and reduce downtime.

Key technical references for the John Deere 250 skid steer lift capacity

| Aspect | Definition / What it Means | Typical Range / Guidance |

|---|---|---|

| Rated Operating Capacity (ROC) | The maximum safe load the loader can lift at a specified height with standard attachments | 2,000–3,000 lbs |

| Lift height at ROC | Vertical reach available at the ROC point | Approximately 8–9 ft (varies by setup) |

| Ballast considerations | Weight added for stability and tipping resistance | Varies by configuration; larger ballast may increase ROC |

| Attachment impact | Mass and balance of the tool attached | Heavier attachments typically reduce ROC at height |

Quick Answers

What is the ROC for the John Deere 250 skid steer?

There is no single ROC value for the John Deere 250; it depends on ballast, tires, and attachments. Always check the data plate for your exact configuration and refer to the load charts.

There isn’t one ROC value for the 250; check the data plate and load charts for your setup.

What factors most influence lift capacity on a John Deere 250?

Ballast, tire choice and pressure, attachment weight, boom angle, and ground conditions all influence lift capacity. These factors interact to shape the ROC for your configuration.

Ballast, tires, attachments, and ground conditions all affect lift capacity.

How can I safely verify lift capacity on-site?

Start with the data plate ROC, confirm ballast and tires, add attachments, and perform a controlled lift at low height, gradually increasing load while watching for instability.

Begin with the plate values and test gradually while watching for instability.

Can ballast changes increase ROC?

Yes, properly added ballast can increase effective ROC within the manufacturer’s stated limits. Always recalculate ROC after any ballast adjustment.

Ballast can raise ROC, but only within safe limits—recalculate after changes.

How does Deere’s lift capacity compare across models?

Larger Deere skid steers typically have higher ROC, but with optimized ballast and attachments the 250-series can handle a wide range of light-to-medium lifts. Compare ROC, lift height at ROC, and stability.

Larger models usually have higher ROC, but the 250 can perform many lifts safely with the right setup.

Where can I find official lift capacity data for the John Deere 250?

Check the operator’s manual and Deere’s official product pages for ROC specifications. Load Capacity, 2026 provides guidance for interpreting these figures across configurations.

Look at the official Deere data and the Load Capacity guide for interpretation.

“Lift capacity on skid steers like the John Deere 250 is heavily influenced by ballast, tires, and reach. Always reference the machine’s data plate and the manufacturer’s load charts for your exact configuration.”

Top Takeaways

- Verify ROC on the data plate before lifting any load

- Ballast and attachment choices significantly affect lift capacity

- Consult Deere’s load charts for your exact configuration

- Use Load Capacity Analysis, 2026 as a reference for planning

- Maintain hydraulics and pins to preserve ROC over time