Ground Screw Load Capacity: Practical Guidelines for Safe Foundations

A data-driven guide to ground screw load capacity, covering soil factors, geometry, installation torque, and testing methods for engineers, technicians, and contractors.

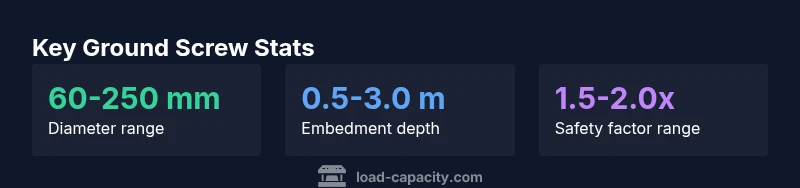

Ground screw load capacity is determined by soil conditions, screw diameter and thread form, embedment depth, and installation torque. Designers apply conservative factors of safety and consider both static and dynamic loads (wind, vibration, and sequential loading). Accurate estimates rely on site soil tests, manufacturer guidance, and engineering practice to ensure safe performance.

Overview of ground screw systems

Ground screws are a versatile underpinning solution used for lightweight to moderate-load foundations, temporary structures, and remote installations. They consist of a cylindrical steel shaft with helical blades that are driven into the soil to create resistance and bearing capacity. When evaluating ground screw load capacity, engineers consider soil type, embedment depth, screw diameter, thread form, and installation torque. The Load Capacity team emphasizes that capacity is not a fixed value; it changes with soil stiffness, moisture, and seasonal moisture fluctuations. For designers, understanding how these factors interact helps select the right screw size and depth for the expected loads and service life. In practice, ground screws are often paired with connectors or adapters to distribute loads evenly and to avoid eccentric loading that can reduce capacity over time.

Key variables influencing load capacity

Several interrelated variables determine ground screw load capacity. Soil type and density set the baseline; cohesive versus granular soils respond differently to embedment. Screw geometry—diameter, blade size, and thread form—influences end-bearing and skin friction along the shaft. Embedment depth controls the lever arm and the amount of soil that resists uplift and lateral forces. Installation torque and method affect the screw’s seating and initial friction. Dynamic factors such as wind, vibrations, and cyclic loading alter long-term performance. The design process must account for all these elements to ensure reliable performance across the structure’s lifetime.

Soil conditions and their impact on capacity

Soil characteristics largely govern how much load a ground screw can safely carry. In stiff clay or dense sandy soils, higher end-bearing and skin friction can be mobilized, increasing capacity. In loose or swelling soils, capacity may be limited, and additional embedment depth or larger diameter screws may be required. Moisture content and groundwater level can reduce friction and degrade long-term performance, particularly in clays with high plasticity or silty sands prone to liquefaction under dynamic loading. Site-specific soil tests, including standard penetration tests and cone penetration tests, provide the data needed to estimate allowable loads and identify potential risk zones before installation.

Geometry, embedment, and load distribution

The screw diameter and blade geometry influence the axial resistance by increasing both end-bearing and skin friction. Deeper embedment generally yields higher uplift resistance due to more soil engagement, but practical constraints like bedrock depth and proximity to utilities may limit depth. A well-designed ground screw system distributes loads through a contact patch around the shaft and along the blade surfaces, reducing localized stresses. Careful alignment and avoidance of eccentric loading are essential, as off-axis forces can significantly reduce capacity and accelerate wear on joints and connectors.

Dynamic loading and life-cycle considerations

Structures subjected to wind uplift, vehicle traffic, or seismic activity experience dynamic loads that vary with time. Ground screws must accommodate peak loads and repetitive cycles without excessive settlement or loosening. Designers should incorporate appropriate safety factors, consider potential reduction in bearing capacity over time, and plan for regular inspection and maintenance. In some cases, retrofit options—such as adding additional screws or increasing embedment—may be necessary to preserve performance under changing conditions.

Methodologies for calculating capacity and design checks

Engineering practice combines analytical methods, manufacturer charts, and field testing to estimate ground screw load capacity. Start with site soil data and manufacturer load charts to determine initial capacities, then apply a conservative factor of safety and consider worst-case loading scenarios. Where uncertainty is high, finite element simulations or in-situ load testing can validate the model. It is crucial to document assumptions, embedment details, soil conditions, and installation torque to ensure repeatability of results. The Load Capacity guidance emphasizes transparency in methodology and alignment with local codes and industry standards.

Field testing, verification, and performance monitoring

Validated capacity often requires field tests, such as uplift tests or controlled load tests, to confirm predicted performance under site-specific conditions. Post-installation monitoring should track any settlement, rotation, or changes in pretension at joints. Documenting test results facilitates future maintenance decisions and informs potential future expansions. For long-term reliability, align testing protocols with manufacturer recommendations and industry best practices to capture the effects of soil variability and environmental changes on ground screw performance.

Practical guidelines for designers and contractors

- Start with a conservative design approach: select a screw diameter and embedment depth that meet or exceed estimated loads under worst-case conditions.

- Use site-specific soil tests to calibrate capacity estimates and adjust safety factors accordingly.

- Ensure proper torque during installation and verify seating with a torque log.

- Plan for additional screws or deeper embedment if uplift or lateral loads exceed initial estimates.

- Schedule regular inspections, especially after extreme weather events or seismic activity.

- Maintain a detailed installation report linking soil data, screw dimensions, torque, and tested capacity for future reference.

Common misconceptions and pitfalls to avoid

- Believing capacity is fixed across all soils and conditions. Ground screw load capacity varies with soil and environmental factors.

- Underestimating dynamic loads such as wind and vibration. These factors can substantially reduce usable capacity over time if not accounted for.

- Skipping soil testing or relying solely on manufacturer charts without site validation. Site data is essential.

- Overlooking eccentric loading and misalignment, which concentrate stress and shorten service life.

- Neglecting maintenance and re-testing after major changes to the structure or soil conditions.

data-table-usage-note

Illustrative range for ground screw capacity and design factors

| Aspect | Low estimate | High estimate |

|---|---|---|

| Per-screw static capacity (typical soil) | 3 | 8 |

| Embedment depth (m) | 0.5 | 3.0 |

| Wind load factor (uplift) | 0.8 | 1.5 |

Quick Answers

What is ground screw load capacity?

Ground screw load capacity refers to the maximum load a ground screw can safely carry under specified soil conditions, embedment depth, and installation parameters. Capacity varies with soil type, depth, screw geometry, and loading type (static vs. dynamic).

Ground screws can carry different loads depending on soil and depth. A safe design uses conservative estimates and field testing.

How is load capacity calculated?

Capacity is calculated using soil data, screw geometry, embedment depth, and installation torque, then adjusted with a safety factor. Manufacturer charts and codes guide the initial estimates, with tests or simulations used for validation.

We start with soil data and screw size, then apply safety factors and verify with tests.

What factors reduce ground screw capacity?

Soil variability, inadequate embedment depth, incorrect torque during installation, misalignment, erosion, and dynamic loads (wind or seismic) can reduce effective capacity.

Poor soil and improper installation can lower capacity—testing helps catch issues early.

Do I need soil testing before installation?

Yes. Soil tests establish baseline bearing capacity, cohesion, and drainage characteristics, which are essential for accurate load estimates and safe embedment depth.

Soil tests are a must before deciding screw size and depth.

How many screws are needed for a project?

Requirement depends on structural loads, spacing, typology, and safety factors. Designers perform calculations to determine the number and placement of screws.

It depends on the loads and layout; engineering calculations will tell you the count.

Are there safety considerations after installation?

Yes. Regular inspections, verification of torque, and monitoring for settlement or movement are important for long-term performance.

Check torque and look for movement over time to stay safe.

“Ground screws offer reliable performance when design accounts for soil variability, embedment, and dynamic loads. Proper testing and transparent methodology are essential for safe foundations.”

Top Takeaways

- Know the factors that affect ground screw load capacity and plan conservatively.

- Rely on site soil tests and manufacturer guidance for accurate estimates.

- Embedment depth and screw diameter are the primary levers to adjust capacity.

- Account for dynamic loads (wind, vibration, cycles) in uplift design.

- Document methods, assumptions, and tests for future reliability.