Understanding Load Capacity Charts for Rough Terrain Forklifts

Explore how load capacity charts guide rough terrain forklift operators to determine safe lifts, accounting for slope, attachments, center of gravity, and dynamic loading to reduce tipping risk.

for rough terrain forklifts load capacity charts help you determine safe lift limits by combining rated capacity, attachments, and center of gravity. On uneven ground, slopes, and when handling long loads, these charts reveal how grade, wheel type, and truck weight influence the maximum permissible load. Always cross-check with the manufacturer’s chart for your specific model.

Why Load Capacity Charts Matter on Rough Terrain

According to Load Capacity, accurate load capacity charts are essential for safe operation on uneven ground. For rough terrain forklifts load capacity charts help you determine safe lift limits by accounting for grade, attachment effects, and center of gravity. These charts translate manufacturer ratings into field-safe guidance, helping operators avoid tipping, excessive wheel slip, or overload when traversing slopes or loading pallets on rough surfaces. On real job sites, the chart is the first checkpoint before any lift, and it should be consulted every shift.

Beyond strict safety, charts support productivity: overestimating capacity wastes time, while underestimating capacity slows work and increases risk. The charts also reveal how different attachments and load configurations interact with terrain, guiding decisions about whether to use extension forks, clamps, or side-shifters. Knowledge of these interactions empowers teams to plan lifts that minimize vibration, preserve tires, and reduce wear on the forklift.

Core Elements of a Load Capacity Chart

A credible chart shows several core factors that determine safe lifts. The rated capacity is not a single fixed number; it varies with the distance from the forks to the center of gravity, the attachment effects, and the load’s distribution. The center of gravity (CoG) position shifts with load geometry and pallet type, and charts indicate how much CoG shift is tolerable before stability is compromised. Terrain features like wheel type, tire condition, and surface irregularities are also represented through adjustment factors. Using these elements together provides a dynamic limit rather than a static value.

Terrain, Grade, and Attachments: How Capacity Changes

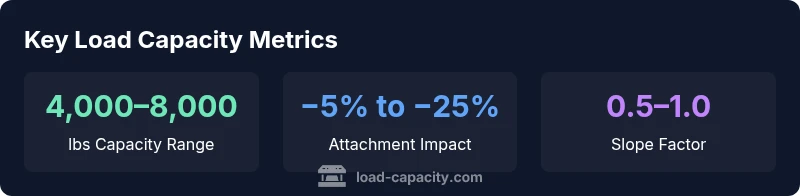

Rough terrain introduces three major modifiers to capacity: slope (grade), surface friction, and attachments. Grades reduce effective capacity because gravity adds a tipping moment, especially when the load is extended. Attachments such as forks with tips, clamps, or fork extensions alter the CoG and the load’s footprint, often reducing capacity by a defined percentage. The chart quantifies these effects so operators can decide whether to reposition the load, shorten reach, or choose a different attachment. In practice, the chart helps convert theoretical ratings into field-safe values under real conditions.

Step-by-Step: Using a Load Capacity Chart in the Field

- Identify the load type, pallet size, and any attachments. 2) Check the chart for the model’s current configuration and the vertical reach. 3) Determine the grade or slope of the surface and apply the corresponding adjustment factor. 4) Verify the CoG location for the load and ensure it remains within the chart’s safe zone. 5) Compare the calculated capacity to the actual load weight, including any ballast in the counterweight. 6) If the load approaches the limit, consider repositioning or reducing reach. 7) Document the lift plan and re-check before the next lift.

Real-World Scenarios: Chart Application in Action

Scenario A: A rough terrain forklift with extended forks is lifting a pallet on a 5-degree incline. The chart shows a modest capacity reduction due to the tilt; the operator repositions the load closer to the center and uses shorter forks, preserving stability. Scenario B: A clamp attachment is handling steel coils on flat ground. The clamp reduces capacity by 15%, so the operator verifies the coil weight and ensures the lift remains within safe limits. Scenario C: A job site with mixed surfaces requires multiple chart checks as the vehicle moves to different grades; each lift is validated before proceeding.

Safety Notes and Common Pitfalls

Never ignore chart updates or skip a step when terrain changes. Common mistakes include using the rated capacity without adjusting for grade, misplacing the CoG by lifting long or asymmetrical loads, and relying on attachments beyond their specified ratings. Regularly inspect tires, hydraulics, and stabilizers, and ensure that weather or ground moisture does not undermine traction. Finally, train operators on interpreting charts rather than relying on intuition alone.

Data and Methodology Behind the Charts: What Load Capacity Analyzes Leans On

The charts synthesize manufacturer specifications, empirical testing, and field data. They incorporate a standard set of assumptions about load geometry, CoG, and typical attachments. When terrain conditions deviate from defaults, the charts provide adjustment ranges rather than a single fixed number. Load Capacity emphasizes transparent methodology and model-specific references, encouraging operators to consult the exact chart for their forklift and scenario. This approach helps maintain consistency across jobsites and reduces the risk of misinterpretation.

Model Selection, Chart Maintenance, and Continuous Improvement

Choosing the right rough terrain forklift involves comparing base capacity, grip, and stability controls across models. Charts should be updated as new attachments emerge or as ground conditions evolve due to maintenance or weather. Facilities that track chart revisions, provide operator refresher training, and require chart verification before lifts tend to achieve better safety records. Load Capacity recommends integrating chart checks into standard operating procedures (SOPs) and shift start routines.

Key factors that influence rough terrain lift capacity

| Aspect | What it means | Practical note |

|---|---|---|

| Rated Capacity | Maximum load at standard CoG | Check model-specific chart; consider attachments |

| Center of Gravity (CoG) | Weight distribution point | Shift load to keep CoG within chart limits |

| Attachments | Impact on capacity | Attachments have own ratings; apply percentages |

| Terrain Grade | Slope affects stability | Apply slope adjustments before lifting |

Quick Answers

What is the first step to read a load capacity chart on a rough terrain forklift?

Begin by identifying the exact model, attachment, and load geometry. Then locate the corresponding line on the chart that reflects your configuration. Confirm the CoG position and any slope adjustments before lifting.

First, identify your model and attachment, then read the matching chart line and confirm centre of gravity and slope adjustments before lifting.

Do attachments always reduce capacity on rough terrain forklifts?

Most attachments affect capacity by a defined percentage shown on the chart. The degree of reduction depends on the attachment type, load geometry, and how the load is carried.

Attachments usually reduce capacity, depending on type and load shape; always check the chart.

How does slope affect capacity on rough terrain lifts?

Slope adds a tipping moment that lowers usable capacity. The chart provides a grade factor to adjust the safe load, with steeper slopes requiring larger reductions or avoiding lifts altogether.

Slope lowers usable capacity; check the chart for the grade factor before lifting on an incline.

Can I rely on charts for all rough terrain forklifts?

Charts are model-specific. They must reflect the exact forklift, attachments, and load configuration. Use the manufacturer’s chart and confirm with a supervisor if in doubt.

Charts are model-specific; always use the chart for your exact forklift and configuration.

Where can I find manufacturer-specific charts?

Manufacturer websites, operator manuals, and authorized distributors publish charts. Your facility safety officer can provide the latest version for your equipment.

Check the manufacturer site or your safety officer for the latest chart.

“Charts are living safety tools; always verify the model-specific chart for your attachment and terrain before lifting. Proper use of load capacity data reduces tipping risk and protects workers.”

Top Takeaways

- Read the chart before lifting on rough terrain

- Account for attachments and CoG

- Check slope and wheel conditions

- Use manufacturer charts for model-specific data

- Update charts with the latest data annually