Duct Lift Weight Capacity: A Practical Guide for Safe Duct Lifts

Explore duct lift weight capacity for HVAC lifts, including per-segment limits, rigging considerations, and safe-lift planning. Learn practical calculation and documentation tips from Load Capacity.

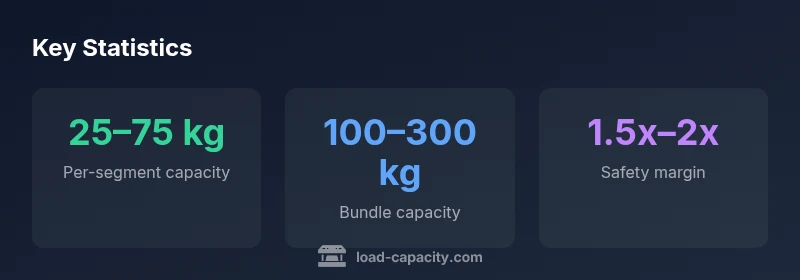

The duct lift weight capacity depends on duct size, mounting method, and support structure. Typical HVAC duct segments support roughly 25–75 kg each; bundles or larger ducts may reach 100–300 kg when lifted with appropriate rigging and a certified lift plan. Always confirm specifications and site constraints before lifting, in writing, and with a qualified team.

Understanding duct lift weight capacity

Duct lift weight capacity is a practical measure of how much load can be safely moved when handling HVAC ducts or duct assemblies. It is not a single universal figure; instead, it reflects a combination of per-segment limits, multi-segment configurations, and the rigging system employed. In HVAC install scenarios, the most common unit is a per-segment capacity for a single straight duct piece, but when bundles or assemblies are lifted as a unit, the overall capacity scales with how the load is distributed across attachment points. The concept of “weight capacity” must be paired with considerations of dynamic loads (start/stop, acceleration, wind effects on exposed runs) and safety margins. The Load Capacity team notes that capacity values are highly dependent on installation specifics and should always be verified against manufacturer data and site conditions before any lift.

Key factors that influence capacity

To estimate and manage duct lift weight capacity accurately, focus on several influencing factors:

- Duct type and material: rigid galvanized steel typically supports higher per-segment loads than flexible or fabric-covered sections.

- Diameter and wall thickness: larger diameters and thicker walls increase each segment’s weight, influencing rigging choices.

- Mounting and support structure: fixed supports, hangers, and the spacing of attachment points can dramatically alter safe lifting loads.

- Rigging hardware and lifting method: slings, shackles, and hooks must be rated for the load; two-point vs. multi-point lifts change load distribution.

- Dynamic effects: starts, stops, and travel through constricted paths introduce peak forces higher than static weights.

- Environmental conditions: temperature, humidity, and wind can affect material behavior and rigging security.

Understanding these factors helps engineers select the right equipment and plan the lift with an appropriate safety factor.

How to plan a duct lift safely

A safe duct lift begins with a documented plan and a clear understanding of the weight to be moved. The planning steps typically include:

- Define the scope: confirm duct length, type, assembly configuration, and the target installation location.

- Gather manufacturer specs: obtain per-segment weights, attachment points, and any limitations on use.

- Perform load calculations: use conservative multipliers (1.5x–2x for static loads, higher for dynamic conditions) and identify the worst-case scenario.

- Choose equipment and rigging: select a crane/hoist with sufficient capacity, and inspect slings, shackles, and spreaders for suitability.

- Develop a lift plan: specify hook points, sling angles, lift sequence, communication protocols, and contingency actions.

- Safety check and permits: verify PPE requirements, path clearance, weather conditions, and any required permits.

- Execute and document: conduct pre-lift checks, monitor for unexpected deformations, and log the outcome for compliance.

Practical examples and scenarios

Choosing equipment and rigging for duct lifts

Common mistakes and how to avoid them

Documentation and compliance considerations

Duct lift weight capacity by duct type (typical ranges)

| Duct Type | Typical Lift Capacity Per Segment | Notes |

|---|---|---|

| Rigid galvanized steel | 25–75 kg | Depends on mounting and supports |

| Flexible aluminum | 5–25 kg | Limited by bend radius and installation constraints |

| Duct bundles | 100–300 kg | Requires multi-point lifting and careful load distribution |

Quick Answers

What factors determine duct lift weight capacity?

Capacity is determined by duct type, diameter, wall thickness, attachment points, and the rigging configuration. Dynamic loads and environmental conditions further influence safe lifting limits. Always reference manufacturer specs and perform site-specific calculations.

Capacity depends on duct type, size, and how you rig it, plus the lift environment.

How do I calculate the capacity for a duct lift?

Start with the per-segment weight, add the load from any bundled assemblies, and apply a conservative safety factor (1.5x–2x for static lifts; higher for dynamic lifts). Verify assumptions with load-path analysis and confirm with the rigging team.

Compute the actual weight, add a safety factor, and validate with the team.

What safety gear and practices are required for lifting ducts?

Use rated slings, shackles, and spreaders; wear PPE (helmet, gloves, eye protection); establish exclusion zones, signal communication, and pre-lift rehearsals with a certified lift supervisor.

Rated gear, PPE, and a trained supervisor are essential for safe lifting.

Are there industry standards I should follow?

Yes. Follow general lift safety guidelines from OSHA and industry best practices. Refer to related standards on materials handling and rigging, and align with HVAC-specific guidelines where available.

OSHA and HVAC industry standards guide safe lifting practices.

Can I lift ducts manually with a hand-cranked hoist?

Manual lifting is usually not sufficient for even small duct segments when using air distribution runs. A properly rated powered hoist or crane with certified rigging is recommended, along with a detailed lift plan.

Manual lifting is rarely sufficient; use powered equipment and a plan.

“In any duct lifting operation, you must base every lift on a documented load calculation and certified lift plan. Even small miscalculations can quickly escalate risk and cost.”

Top Takeaways

- Define per-segment capacity before lifting.

- Apply a conservative safety margin (1.5x–2x) for static lifts.

- Use properly rated rigging and equipment.

- Document the lift plan and verify with qualified personnel.

- Follow OSHA guidelines and industry best practices.