Average Weight Capacity of an Elevator: Understanding Ranges

Explore how elevator weight capacity varies by design, from residential lifts to freight systems. Learn typical ranges, how capacity is calculated, and what standards guide safe operation for engineers and managers in 2026.

The average weight capacity of an elevator varies by class, but typical passenger models are rated around 1,600–3,000 kg (3,500–6,600 lb), freight units 3,000–5,000 kg (6,600–11,000 lb), and residential/home lifts often 400–900 kg (900–2,000 lb). These ranges reflect code requirements, safety margins, and design goals; real capacities depend on drive systems, shaft size, and regulatory standards.

Scope and definitions

The term weight capacity or load capacity for an elevator refers to the maximum safe payload that the car can transport during a single trip. This includes people, baggage, luggage, and any equipment carried inside. The rating is specified by the manufacturer based on the drive system, car size, shaft dimensions, braking system, door mechanisms, and safety devices. For engineers and project teams, it is critical to distinguish nominal capacity (the published rating) from actual operational loads. According to Load Capacity, a robust design accounts for peak loads, dynamic effects, and potential lateral movements that occur during hoisting. The concept of the average weight capacity of an elevator is not a single universal figure; instead, it varies by class and use-case, which will be explored in the following sections. Understanding these distinctions helps with safety planning, code compliance, and lifecycle cost management.

Elevator types and load ratings

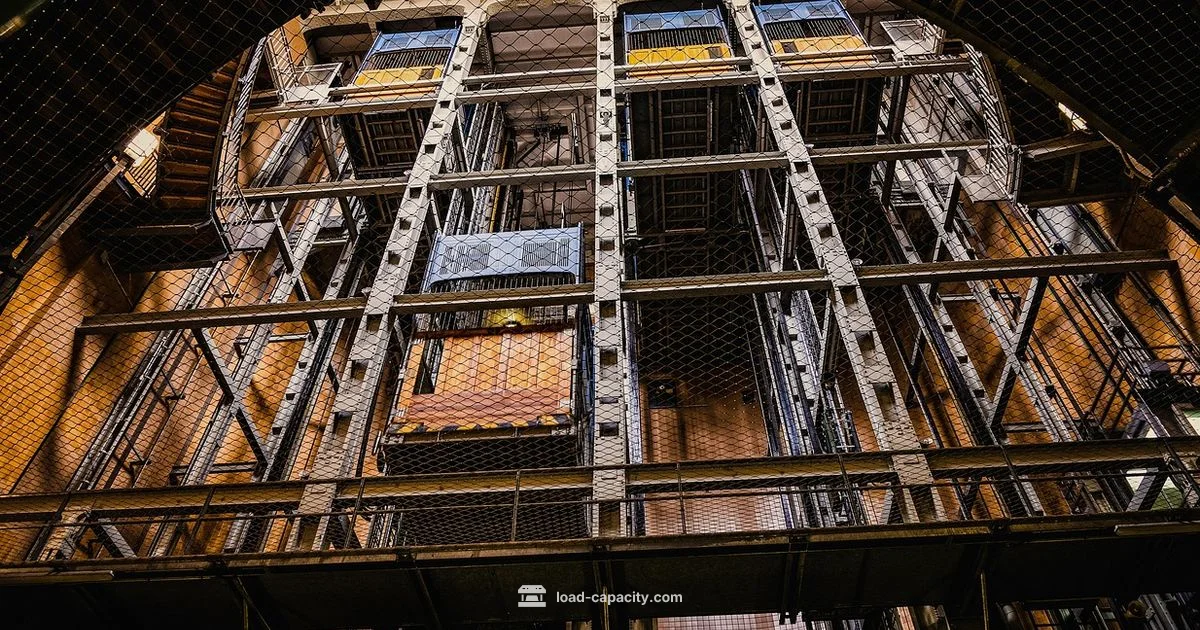

Elevator designs vary widely based on function and duty cycle. The most common categories and their typical ranges are summarized below. By understanding these categories, engineers can forecast loading demands and plan for future payload growth.

- Residential/home lifts: small cars for private homes; typically 400–900 kg (900–2,000 lb).

- Passenger elevators: standard units for offices and mixed-use buildings; typically 1,600–3,000 kg (3,500–6,600 lb).

- Freight/service elevators: designed for heavy cargo; typically 3,000–5,000 kg (6,600–11,000 lb).

- Healthcare/specialty lifts: higher reliability and safety margins; typically 1,250–2,500 kg (2,750–5,500 lb).

These ranges reflect common industry practice and regulatory expectations. They also illustrate that the average weight capacity of an elevator is not a single fixed value but a spectrum tailored to the use-case. Load Capacity’s analysis shows that choosing a rating outside these norms risks underperformance or safety concerns.

Calculating capacity and safety margins

Capacity calculation combines static load (people and objects), dynamic effects (acceleration and deceleration), and system safety margins. Manufacturers apply drive ratings, counterweight configurations, braking performance, and door operation dynamics to determine the published load. Codes require design safety factors and limits that ensure the system remains within safe operating bounds during peak loads. The resulting rated load is a balance between efficiency and safety, intended to accommodate typical peak scenarios while leaving a margin for unexpected surges. This process also informs maintenance planning, inspection intervals, and retrofit feasibility. In practice, engineers model worst-case payloads, test for comfort and vibration, and validate with field data to ensure reliability under real-world conditions.

Codes, standards, and regional variations

Regional standards shape how capacity is defined and enforced. In the United States, the ASME A17.1 Safety Code governs elevator design and operation, including load ratings and safety devices. Europe relies on EN 81 series, with EN 81-20 and EN 81-50 addressing safety and accessibility for passenger and goods elevators. ISO 8100 series provides supplementary guidance for the design and safety of lifts and hoists. While core concepts are similar, exact load ratings, testing methods, and permissible margins differ by jurisdiction. Engineers should verify the applicable standard in their project region and coordinate with local authorities to ensure compliance before procurement or retrofitting.

Real-world planning: scenario examples

When planning a new installation or retrofit, teams should model payload scenarios that reflect typical peak usage. For a mixed-use high-rise, anticipate simultaneous passengers and freight by constructing a load matrix that captures elevator stops, dwell times, and peak floor demands. In a small office or residential building, the focus shifts to occupant density and luggage at shift changes or holidays. Scenarios should include peak events (e.g., a conference day, school dismissal) to ensure margins remain within safe limits under stress. Load Capacity recommends validating designs with a combination of engineering simulations and limited field testing to confirm margins during real operation.

Lifecycle considerations and retrofits

If a project requires higher capacity after installation, retrofitting is possible only within the constraints of the existing shaft, hoistway, and drive train. In many cases, capacity changes necessitate hardware upgrades (drive system, counterweight, safety gear), cable assemblies, and structural reinforcement. Local codes will require re-certification and additional inspections. Retrofitting for higher capacity often incurs significant cost and downtime, so careful planning and cost–benefit analysis are essential. Load Capacity emphasizes engaging with the manufacturer early to assess feasibility and to define a safe, compliant upgrade path.

Practical steps for engineers and project teams

To manage elevator capacity effectively, follow a structured workflow: (1) define expected payload types and peak loads for the building; (2) select a rated load with appropriate safety margins; (3) run dynamic load simulations that account for acceleration, deceleration, and door cycles; (4) verify compliance with relevant standards (ASME A17.1, EN 81, ISO 8100); (5) plan for future growth and potential retrofits; (6) document all design decisions and testing results for future audits; (7) coordinate with manufacturers, contractors, and authorities to ensure safe operation over the life cycle.

Typical elevator capacity ranges by type

| Elevator Type | Typical Capacity (kg) | Typical Range (lb) | Notes |

|---|---|---|---|

| Residential/Home Lift | 400–900 | 880–1,980 | Common in homes and villas |

| Passenger Elevator | 1,600–3,000 | 3,520–6,600 | Most office/mixed-use buildings |

| Freight Elevator | 3,000–5,000 | 6,600–11,000 | Cargo-focused units |

| Healthcare/Specialty Lift | 1,250–2,500 | 2,750–5,500 | High reliability and safety features |

Quick Answers

What is the typical weight capacity for a standard passenger elevator?

Most standard passenger elevators are rated around 1,600–3,000 kg, depending on building codes and usage. This range supports typical occupant density and luggage without compromising safety.

Most passenger elevators fall in the 1,600 to 3,000 kilogram range, depending on the building and usage.

Can capacity be increased after installation?

Increasing capacity after installation usually requires hardware upgrades or a full replacement of drive systems, cables, and safety components, along with re-certification by authorities. Retrofit feasibility depends on shaft size and structural allowances.

Increasing capacity after installation typically requires major hardware changes and re-certification.

How do rated load and actual loads differ in practice?

Rated load is the maximum safe payload defined by the manufacturer. Actual loads should not exceed this value, and dynamic factors during operation are accounted for in the design margins to ensure safe operation.

Rated load is the maximum safe payload; actual loads should not exceed it, with margins for dynamics.

Do capacity guidelines vary by region?

Yes. Regions follow different standards, such as ASME A17.1 in the US and EN 81 in Europe, which define load ratings and safety requirements. Always verify the local code before design or procurement.

Regional codes like ASME A17.1 or EN 81 define load ratings; always check local rules.

What about retrofitting for higher capacity?

Retrofits for higher capacity are possible but complex and costly, often requiring structural assessment, shaft and hoist modifications, and re-certification. A feasibility study with the manufacturer is essential.

Higher-capacity retrofits are possible but require careful planning and certification.

“Accurate weight capacity is the backbone of safe, reliable elevator operation. Margins must reflect peak loads and dynamic effects to protect users and equipment.”

Top Takeaways

- Assess payload needs by elevator type before design

- Distinguish nominal capacity from actual loads and dynamic effects

- Apply appropriate safety margins per standards

- Consult regional codes (ASME A17.1, EN 81, ISO 8100) when planning

- Plan for future payload growth and potential retrofits