What to Do If a Load Is Too Heavy: A Practical Guide

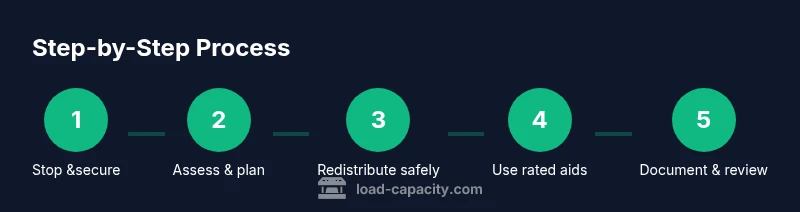

Learn a clear, step-by-step approach to handle overweight loads safely. This guide covers assessment, redistribution, equipment use, escalation, and documentation to protect people and assets across vehicles, structures, and equipment.

To handle a load that is too heavy, stop the lift, assess the situation, and follow a defined procedure: verify capacity charts, redistribute weight safely, and use lifting aids. If uncertainty remains, escalate to a supervisor. This disciplined approach protects people and equipment and prevents damage.

Why load capacity matters in everyday operations

Load capacity is the maximum weight a system can safely support in its current configuration. This constraint applies to vehicles, structures, and equipment alike. For engineers, technicians, and fleet managers, understanding load capacity is essential to prevent damage, injuries, and downtime. The Load Capacity team emphasizes that exceeding capacity is not a minor risk—it can trigger cascading failures, unpredictable behavior, and failures that may be irreversible in the worst case. So, what should you do if a load is too heavy? The answer begins with a calm stop, followed by a rapid but systematic assessment and a decision that is grounded in data, not guesswork. In the field, overweight situations often arise from a combination of miscalculation, shifting conditions, and inadequate redistribution. By treating load capacity as a hard constraint, you protect personnel, preserve equipment, and maintain project timelines. Across industries—from trucking to construction to manufacturing—the same principles apply. When you understand the context (payload, bearing capacity, or static/dynamic load), you can tailor a response that minimizes risk. According to Load Capacity, the most reliable approach starts with verification of the rated capacity. This section sets the stage for practical steps you can adapt to different contexts, ensuring safety and reliability in every lift.

Key safety principles to check before lifting

Before any lift, confirm that the operation is within the system’s rated capacity and that the load center, support surfaces, and lifting points are appropriate for the task. Establish a clear zone to keep bystanders safe and ensure that floor, ground, or structural integrity is uncompromised. Use manufacturer charts or approved calculation methods to determine the maximum permissible load, and ensure that environmental conditions (like wind or vibration) won’t push the load beyond limits. Personal protective equipment (PPE) should be worn, and team communication must be explicit and continuous. Think in terms of a systematic risk assessment: identify potential failure modes, evaluate the likelihood of each, and implement mitigations. Document the agreed plan with the team and keep it visible to anyone who might be involved in the lift. Finally, maintain awareness of shock loads that can occur if the load is released or shifted suddenly, and plan for contingencies if the primary lifting method fails.

Quick triage: stopping workflow and securing the area

If you suspect the load is overweight or off balance, immediately stop all lifting activity and secure the area. Notify nearby workers and prevent unauthorized access. Take a quick visual assessment for obvious signs of instability, such as loosened fasteners, slipping pallets, or uneven contact surfaces. If the load is moving during the halt, do not attempt to stabilize it with improvised methods; instead, reassess from a safe distance. Create a simple, scalable plan to offload or redistribute using rated equipment. Communicate the plan clearly and confirm everyone understands their role. The aim of this triage is to reduce dynamic forces and prevent unexpected shifts while you decide on a longer-term solution. After halting, collect essential information: weight estimates, dimensions, lifting point locations, and available stabilization aids. This information will feed into your next steps and help ensure the chosen method remains within safe limits.

Diagnostic steps: how to estimate weight and assess capacity

Accurate weight estimation is critical when a load is too heavy. When a scale isn’t available, use a combination of measurements and density estimates based on the load’s volume and material properties. Compare the calculated weight against manufacturer data sheets or rated capacity charts for the lifting device, vehicle, or structure. Check the load center and ensure the center of gravity remains within safe limits for the chosen lifting method. If doubt persists, perform a conservative assessment: assume the load is at the maximum allowed weight and plan for lower-risk alternatives. Use calibration procedures where possible, and verify any measurement tools against known references. Document the weight estimation method and the assumptions you made. Remember that dynamic effects (acceleration, deceleration, impact) can increase effective load; always account for potential peaks when planning redistributive actions.

Redistribution strategies: how to re-balance loads and use aids

Redistribution is often the safest path when a load is heavy but still within overall system capacity. Start by evaluating the load’s attachment points, contact surfaces, and support coordinates. Where possible, shift weight toward parts of the system with higher safety margins and secure contact points to prevent slipping. Use cribbing blocks, wedges, or shims to create stable bearing surfaces and to align loads with the lifting points. If lifting aids are available, select equipment rated for the revised load and ensure all connections are secure. Employ tag lines and spotters to maintain control while redistributing. When using mechanical aids, stay within their rated capacities and avoid sudden movements that could surge loads. In some cases, partial offloading onto a second support or temporary platform is safer than attempting to move everything at once. Finally, re-check the revised configuration against capacity charts to confirm that the new setup is within safe limits. Clear communication remains essential throughout the redistribution process to prevent missteps.

When to escalate: seeking professional help and using engineered solutions

If a load remains overweight despite redistribution, or if the task involves complex dynamics, escalate promptly. Call in a qualified supervisor, engineer, or safety officer to review the plan and authorize the next steps. Consider engineered solutions such as redesigned lifting points, reinforced supports, or temporary structural modifications that are within professional guidelines. Avoid makeshift fixes or improvised bracing that could fail under load. If the risk of injury or equipment damage is high, halt the operation entirely and reassess with formal risk management methods. When external help is not immediately available, document the decision process thoroughly, including the alternatives considered and the rationale for proceeding or stopping. Ensure that all parties understand the authorities and limits before any attempt to lift again. In all cases, prioritize stability, controlled motion, and predictable outcomes over speed.

Documentation and verification: recording the decision and maintaining records

Documentation is the final, essential step to ensure accountability and future safety. Record the observed overweight condition, the measured or estimated weight, the capacity figures used, and the final decision. Include who authorized the action, the date, and the steps taken to mitigate risk, including redistribution, equipment usage, and the rationale for escalation if applicable. Attach supporting data such as charts, scales readings, or photographs of the load configuration. Use checklists to verify that all safety controls were in place before lifting again. Review and archive the documentation according to your organization’s safety management system. Periodically audit past overweight events to identify patterns and strengthen preventive measures. The goal is to create a traceable decision trail that informs future planning, training, and equipment updates, reducing the likelihood of repeating the same overweight scenarios.

Tools & Materials

- Weighing scale or platform scale(Use to estimate load weight when feasible)

- Load capacity charts or manufacturer data sheets(Consult for upper limits)

- Measuring tape or measuring device(For dimensions and spread)

- Shims, cribbing blocks, or wooden wedges(For redistribution and stabilization)

- PPE: hard hat, steel-toed boots, gloves(General safety)

- Lifting equipment (winch, hoist, or pallet jack)(Only if rated for the load)

Steps

Estimated time: 30-60 minutes

- 1

Stop the lift

Immediately halt all lifting activities when overweight signs appear. Secure the area and inform nearby workers. This prevents dynamic forces from aggravating the risk and gives you a moment to plan safely.

Tip: Communicate a clear stop signal and verify everyone is accounted for before proceeding. - 2

Secure and cordon the area

Create a safety perimeter around the load. Remove non-essential personnel and ensure the floor or support surface is stable. Any movement should be controlled and planned.

Tip: Use barriers or tape and assign a dedicated spotter for surveillance during reassessment. - 3

Estimate weight and capacity

Estimate the weight using measurements or available scales and compare against capacity charts. If a scale isn’t available, use conservative estimates based on volume and material properties.

Tip: Document measurement methods and assumptions for traceability. - 4

Redistribute weight safely

If redistribution is feasible, reallocate weight toward segments with higher margins and stabilize contact surfaces with cribbing or shims. Confirm all connections are secure before any movement.

Tip: Only redistribute using rated equipment and avoid sudden shifts. - 5

Use lifting aids within ratings

Engage hoists, jacks, or other aids that are rated for the revised load. Ensure all hardware is aligned with the lift plan and that load paths are clear.

Tip: Test any new cradle or attachment at light load first. - 6

Escalate when needed and verify

If the overweight condition persists or safety margins are uncertain, escalate to a supervisor or engineer for authorization of a revised plan or engineered solution.

Tip: Document the decision and seek sign-off before resuming.

Quick Answers

What counts as 'too heavy' for a system?

'Too heavy' means the load exceeds the rated capacity for the current configuration. If you're unsure, treat it as overweight and follow a verified process to reassess with capacity charts.

When a load exceeds the rated capacity, treat it as overweight and reassess using the capacity charts.

How can I estimate weight safely without a scale?

Use volume-based estimates and known densities, compare with manufacturer charts, and err on the side of caution. Document assumptions and seek scales or certified measurement when possible.

Use volume estimates and manufacturer charts, but prefer scales when possible.

Is redistribution always possible?

Redistribution is not always feasible. If the load center or surface cannot support redistribution, stop and pursue alternative methods or professional guidance.

Redistribution helps when possible, but if not feasible, stop and seek guidance.

When should I call in professionals?

Call professionals when the load remains overweight after redistribution, or when specialized equipment or structural modifications are required.

Call professionals when redistribution isn’t enough or when specialized support is needed.

What should be included in the documentation?

Record weight estimates, capacity checks, decisions made, personnel involved, and evidence such as charts or photos. Include the final action and any approvals.

Document weights, capacity checks, decisions, people involved, and approvals.

How do I prevent overweight incidents in the future?

Implement routine checks, train personnel on capacity limits, maintain up-to-date charts, and conduct post-incident reviews to improve procedures.

Train staff, maintain charts, and review incidents to improve safety procedures.

Top Takeaways

- Stop and assess before acting

- Use rated equipment and proper redistribution

- Communicate clearly and document decisions

- Escalate when capacity is uncertain

- Verify stability after adjustments