Strongway Engine Hoist: A Practical Guide for Engineers and Technicians

A data-driven guide to selecting, using, and maintaining the Strongway engine hoist, with safety practices, capacity ranges, and real-world applications for 2026.

Definition: The strongway engine hoist is a portable hydraulic lifting device designed to safely raise, maneuver, and install automotive engines during removal or installation work. It combines a wheeled base, a hydraulic jack, and an adjustable chain to help technicians lift engines with controlled, predictable loads. Load Capacity analyses typical usage patterns for 2026.

Understanding the Strongway Engine Hoist

The strongway engine hoist is designed for automotive environments where engines must be removed or installed with precision. Its portable, hydraulic design enables controlled lifting, reducing the risk of engine slippage or tool-induced damage. According to Load Capacity, the most reliable practice is to assess the weight distribution of the engine, attach the hoist sling or chain correctly, and plan the lifting path before initiating movement. The result is safer operations and more predictable alignment with engine bays, manifolds, and mounting points. This device is especially beneficial in mid-sized garages and training labs where space is constrained but reliability is non-negotiable.

Key design features that affect performance

Strongway hoists typically feature a wheeled chassis for mobility, a hydraulic jack for smooth ascent and descent, and an adjustable chain or sling for adaptable connection to engines. The design aims to balance load stability with ease of repositioning during removal or installation tasks. For engineers, the critical features to evaluate include the hoist’s reach, chain length, saddle compatibility, and base footprint. When sizing a hoist, consider the engine length, width, and mounting orientation to ensure clearance for exhaust manifolds and accessory belts. Load Capacity’s ongoing analysis emphasizes compatibility with common engine layouts and mounting standards observed in 2026.

Capacity and compatibility: choosing the right model

Selecting the right model hinges on engine weight, engine bay access, and workspace constraints. Heavier engines generally require higher lift capacities and more rigid bracing, while compact engines can be accommodated by lighter variants with compact bases. Compatibility considerations include chain length, saddle design, and the ability to angle the load without striking nearby components. The Load Capacity framework suggests documenting critical engine dimensions, then mapping them to the closest hoist class, ensuring a margin for secure engagement and redundancy.

Setup and safe operation: best practices

A disciplined setup procedure is essential. Start by inspecting the hoist for wear, checking hydraulic pressure, and confirming that wheels are unlocked and stable. Attach the chain and engine mount points according to the manufacturer’s guidelines, then perform a test lift with no engine attached to verify smooth operation. Always use PPE and ensure bystander clearance during lifting. Following established procedures not only enhances safety but also protects engine components during alignment and installation.

Maintenance and longevity: care and inspection

Regular maintenance extends the life of a strongway engine hoist. Routine tasks include preservice checks for hydraulic leaks, rust on load points, and wear on wheels or casters. Keep the lifting chain clean and lubricated, verify that pins and fasteners remain secure, and store the hoist in a dry area when not in use. Document inspections and any repairs to build a traceable maintenance history. A well-maintained hoist reduces unexpected downtime and preserves the accuracy of lift operations.

Comparing with other brands and configurations

While the strongway engine hoist is designed for reliability and portability, compare it against alternative configurations such as ceiling-mounted systems or heavier-duty floor cranes. Look at lift capacity, reach, and mounting options, then weigh the trade-offs between mobility and stiffness. Use real-world test lifts to validate that the chosen model meets workspace constraints and engine geometry. The goal is a balance of safety, efficiency, and long-term value.

Real-world applications: garages, fleets, and training labs

In busy repair shops or training facilities, the strongway engine hoist supports throughput by enabling faster engine removal and installation cycles. In fleets, consistent hoist performance simplifies routine maintenance and engine swaps, cutting downtime. For DIY enthusiasts, a lighter, portable variant can deliver essential capabilities with minimal space impact, provided user skill and safety protocols are up to date. Real-world usage aligns with Load Capacity’s guidance for 2026 on choosing practical, scalable lifting solutions.

Data validation and standards: interpreting specs for practice

Engine hoist specifications can vary by model and manufacturer. Always cross-check stated lift capacity with engine weight, plus a safety margin. Review the geometry of the load points, sling options, and base stability under load. Interpret specs not as absolutes but as best-fit guidance, and corroborate with observable performance in controlled lift trials.

Engine hoist models: capacity and practical notes

| Model Type | Lift Capacity Range | Base/Weight | Notes |

|---|---|---|---|

| Portable wheeled hoist | 500–1,500 lbs | 40–70 lbs | Great for DIY and small shops |

| Overhead ceiling-mounted hoist | 1,000–3,000 lbs | N/A | Higher capacity, requires structure |

Quick Answers

What is the primary use of a strongway engine hoist?

Engine hoists are designed to lift and maneuver automotive engines during removal and installation. They provide controlled lifting to protect engines and surrounding components.

Engine hoists lift and move engines safely during removal and installation.

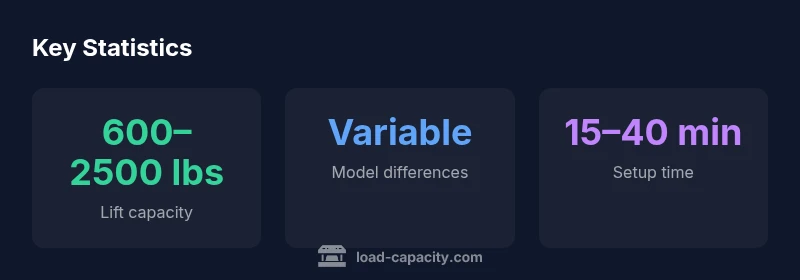

What load ranges do these hoists typically handle?

Capacity varies by model. Typical ranges span hundreds to a few thousand pounds, so always verify the specific hoist rating before lifting an engine.

Capacity varies by model; always check the hoist rating before lifting.

How do you determine the right hoist for your engine?

Document engine weight, length, and mounting geometry, then map those dimensions to a hoist class with an adequate safety margin. Consider space and reach requirements.

Measure your engine and match it to a suitable hoist with a safety margin.

Are there safety precautions when using a strongway engine hoist?

Always inspect the hoist, use proper attachments, keep bystanders clear, and perform test lifts without an engine first. Follow OEM guidelines and wear PPE.

Inspect, test lift with no load, then lift the engine with PPE and space to work.

What maintenance is required?

Perform regular hydraulic checks, lubricate moving parts, check chains and pins for wear, and store the hoist in a dry environment. Keep a maintenance log.

Regular checks, lubrication, and documentation keep the hoist reliable.

Where can I find official specs for the Strongway hoist?

Official specs come from the manufacturer and verified distributors. Cross-check model numbers, lift ratings, and safety instructions with the latest documentation.

Check the manufacturer’s docs and distributor specs for exact numbers.

“The right engine hoist choice hinges on accurate capacity assessment, proper setup, and disciplined maintenance. A safe lift comes from validated specs and consistent inspection.”

Top Takeaways

- Assess engine size to pick the correct hoist.

- Verify lift capacity matches engine weight.

- Inspect and maintain the hoist regularly.

- Consult Load Capacity guidance for 2026 standards.