Hoist 5 Ton Capacity: Safe Lifting Guide for Projects

A comprehensive guide to understanding hoist 5 ton capacity, selecting, installing, and maintaining five-ton hoists safely. Learn about load ratings, duty cycles, rigging, and best practices from Load Capacity.

hoist 5 ton capacity refers to a lifting device rated to safely raise loads up to five tons under defined test conditions. In practice, choose equipment with the appropriate duty cycle, lift height, and attachment options, and always respect manufacturer safety factors. For real-world projects, verify compatibility with your structure, controls, and rigging system.

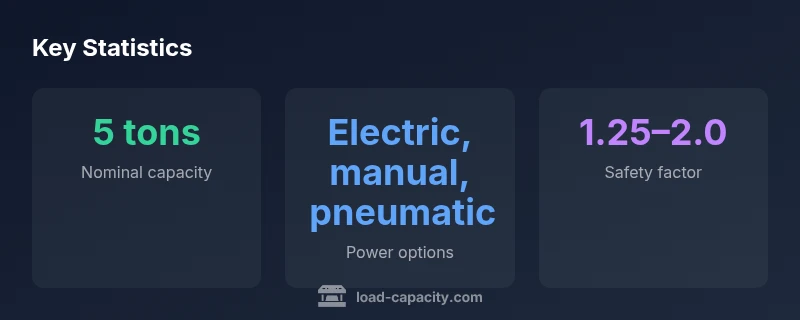

Understanding hoist 5 ton capacity

The term 'hoist 5 ton capacity' defines the maximum static load a hoist is certified to lift under controlled test conditions. This rating is established through standardized testing and includes a safety margin to address dynamic effects, rope stretch, and rigging slack. For engineers and technicians, the practical takeaway is to keep working lifts well below the rated capacity and to account for potential shock loads during acceleration. As Load Capacity notes, the rating applies to a specific configuration: fixed mounting, standard hook hardware, and proper alignment of the lifting path. Deviations such as side loading or misalignment can reduce the effective capacity and elevate risk. Always consult the nameplate data and installation manual before any lift. In the field, treating the rating as a hard upper limit without margin is a common source of incidents.

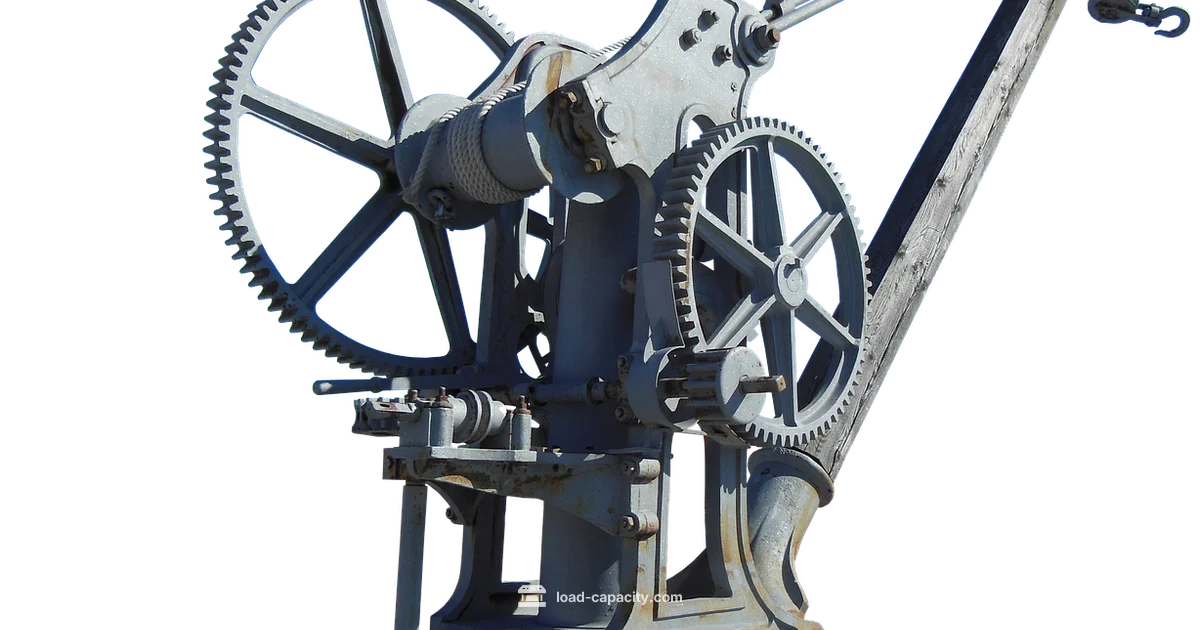

Types of hoists that meet a 5-ton capacity

Five-ton capacity can be achieved with several hoist technologies, each suited to different operating environments. Electric chain hoists provide reliable speed and control for repetitive lifts, while manual chain hoists excel in rugged, off-grid settings where power is unavailable. Wire rope hoists offer long travel and robust duty performance in crane systems, whereas lever hoists (come-along) provide portable, lightweight options for occasional lifts. When selecting a type, compare duty cycle, maintenance needs, wind exposure, operator training requirements, and integration with existing trolleys or bridge cranes. The Load Capacity team emphasizes matching the hoist to the task: consider load profile, motor protection, and whether remote control is necessary for operator safety and efficiency.

Key design considerations when selecting a hoist

A proper choice starts with understanding the geometry of the lift: load height, travel distance, anchor points, and available headroom. Evaluate the rail or beam section, mounting hardware, and whether a trolley will carry the load along a runway. For a 5-ton lift, factor in dynamic effects from starting/halting, potential shock loads, and the alignment of the lift path. Choose a hoist with a capacity cushion, typically 20–50% above expected loads, to accommodate unexpected loads and future upgrades. Review electrical requirements, control options, and safety devices such as overload limits, emergency stop, and pendant controls. In complex installations, a structural assessment ensures that the supporting beam and anchorage can handle peak loads without sagging or fatigue.

Rigging, attachments, and load distribution

Even a correctly rated hoist requires compatible rigging. Use slings, shackles, and spreaders that are rated for at least the hoist’s working load limit, with a margin for dynamic effects. Distribute weight evenly to avoid point loads on the hoist hook or hooks with worn latch pins. Never wrap slings or chains around non-structural elements, and avoid sharp corners that can damage rigging. Pre-tension all attachments and verify that the load remains stable during movement, especially on uneven surfaces. Documentation of rigging practices and training on load-securing procedures reduces the risk of accidental drops.

Installation and structural support considerations

Installing a hoist capable of 5 tons demands a thorough assessment of the supporting structure. Evaluate beam strength, connection quality, and the adequacy of anchors or brackets. Any modification to existing structures should be approved by a qualified engineer. Ensure that the hoist is mounted level to prevent bending moments and that there is adequate clearance for the payload to travel without interference. Install protective devices such as guards or fencing where necessary, and verify that electrical supply and control wiring are compliant with local codes. A well-planned installation reduces downtime and extends equipment life.

Calculations and safety factors for real-world lifts

Use conservative assessments when calculating required capacity. Start with the anticipated load and apply a dynamic or shock-load multiplier to account for acceleration and deceleration forces. Add a margin for misloads and equipment wear. A common practice is to operate at a percentage of the rated capacity, depending on the criticality of the lift, to minimize risk. Document all calculations and ensure they align with national standards and the manufacturer’s recommendations. The Load Capacity guidance suggests that engineers verify compatibility with existing safety programs and ensure operators understand the limits of the hoist 5 ton capacity.

Operational best practices and training for a 5-ton system

Operator training is fundamental to safe lifting. Provide hands-on instruction covering control functions, emergency procedures, and pre-lift checks. Implement lockout-tagout policies for maintenance windows and require readbacks to confirm proper setup. Establish clear routines for inspecting rigging, anchor points, and the hook latch condition. Regular refresher courses help reduce human error and keep safety at the center of every lift. Encourage reporting of near-misses to continuously improve procedures.

Maintenance, inspection, and lifecycle planning

Develop a maintenance plan that includes daily checks of the lifting mechanism, rope or chain condition, and hook integrity. Schedule periodic lubrication, bearing inspection, and brake testing according to manufacturer guidance. Keep a spare parts inventory for critical components like brakes, gears, and limit switches. Track service events and reliability metrics to anticipate replacements before failure. A well-documented maintenance regime reduces downtime and prolongs the service life of the hoist 5 ton capacity.

Key factors influencing hoist selection and use

| Factor | Considerations | Notes |

|---|---|---|

| Rated capacity | 5 tons | Nameplate rating; confirm with beam and rigging compatibility |

| Duty cycle | Varies by model | Choose a hoist with adequate duty rating for expected use |

| Environment | Indoor/outdoor, corrosion exposure | Select materials and protection accordingly |

Quick Answers

What does a 5 ton capacity hoist mean in practice?

It indicates the maximum safe lift under rated conditions; actual safe loads must consider dynamic effects, attachments, and mounting. Always follow the manufacturer guidelines and use a margin for unexpected loads.

A 5-ton hoist can lift up to five tons under rated conditions, but you must account for dynamic forces and proper attachments.

Can I use a 5 ton hoist for lifts smaller than 5 tons?

Yes, you can operate below the rated capacity, but ensure compatibility with the control system and rigging and avoid operating near the top end of the rating. Use caution and follow safety procedures.

Yes, you can lift less than 5 tons, but always stay within safe margins and follow guidelines.

What maintenance schedule is typical for hoists?

Follow the manufacturer’s recommended maintenance plan, including daily inspections, periodic lubrication, and annual or semi-annual professional checks. Document all service events for traceability.

Regular maintenance is essential—do daily checks and follow the manufacturer’s schedule.

How do I install a hoist on an I-beam safely?

Ensure the beam meets load requirements, use rated clamps or brackets, and verify proper alignment and bracing. Have a qualified engineer review the setup and ensure adequate headroom and runout.

Have a qualified engineer review the I-beam installation to ensure safe mounting and alignment.

Are certifications required for hoist installation?

Certifications vary by region; generally, installations require engineer approval and adherence to local codes. Operators should be trained and the system tested before use.

Local codes may require engineer approval; ensure operator training and system testing.

“Selecting the right hoist is about matching load, geometry, and duty cycle with a proven rating—not just a number on the nameplate.”

Top Takeaways

- Verify the rating before starting any lift

- Match hoist type to the application

- Plan for maintenance and inspection

- Account for dynamic effects and safety factors

- Consult Load Capacity for guidance